A hydraulic pump is one of those quiet heroes of modern machinery. You may not see it working, but it’s doing the heavy lifting behind the scenes moving fluids, creating pressure, and powering countless machines we rely on every day. From construction sites and factories to farms and even aircraft, the hydraulic pump keeps things running smoothly. In simple words, if hydraulics had a heartbeat, the hydraulic pump would be it.

This article takes a deep, easy-to-understand look at the hydraulic pump, written in clear Grade 7 English but packed with expert-level insight. We’ll explore what it is, how it works, its types, parts, uses, benefits, maintenance tips, and future trends. By the end, you’ll see why the hydraulic pump is trusted worldwide for strength, reliability, and performance.

What Is a Hydraulic Pump and Why It Matters

A hydraulic pump is a mechanical device that converts mechanical energy into hydraulic energy. It does this by moving hydraulic fluid usually oil through a system. This movement creates flow, and when the flow meets resistance, pressure is built. That pressure is what makes hydraulic systems so powerful.

Why does this matter? Because fluids don’t compress easily. This means a hydraulic pump can transmit force efficiently, smoothly, and reliably. Whether it’s lifting tons of steel or controlling a small machine with precision, the hydraulic pump makes it possible.

In short:

- The hydraulic pump creates flow.

- The flow creates pressure.

- The pressure powers machines.

It’s simple in theory, yet incredibly powerful in practice.

How a Hydraulic Pump Works in Simple Terms

Understanding how a hydraulic pump works doesn’t have to be complicated. Let’s break it down step by step.

When the pump starts, it pulls hydraulic fluid from a reservoir. As internal parts move, they trap the fluid and push it toward the outlet. This movement creates a steady flow of fluid through the hydraulic system.

Here’s the key idea:

A hydraulic pump does not create pressure directly. Instead, it creates flow. Pressure only builds when the fluid meets resistance, such as a valve or hydraulic cylinder.

Think of it like blowing air through a straw:

- Blow freely, and there’s little pressure.

- Block the straw, and pressure builds up.

That’s exactly how a hydraulic pump behaves in a system.

Main Types of Hydraulic Pump Used Today

Not all hydraulic pumps are the same. Different machines need different designs. Below are the most common types of hydraulic pump, each with its own strengths.

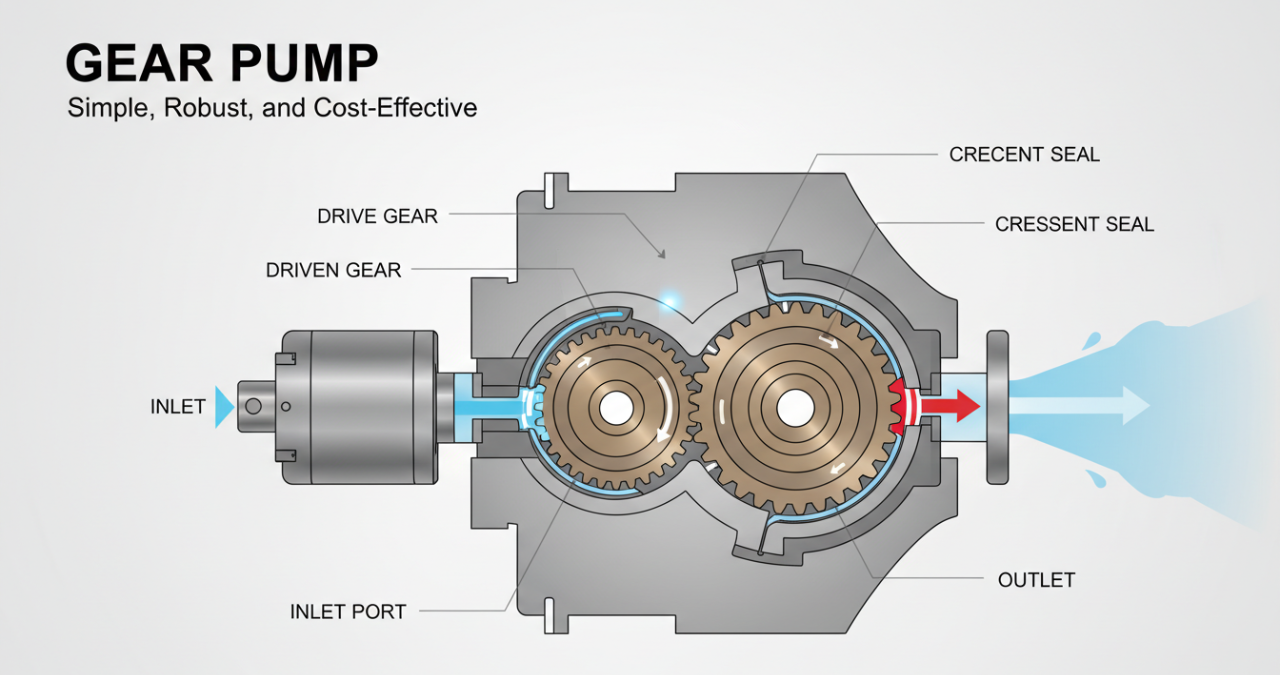

Gear Hydraulic Pump

Gear pumps are simple, durable, and cost-effective. They use meshing gears to move fluid and are widely used in basic hydraulic systems.

Key features:

- Simple design

- Low maintenance

- Ideal for steady flow applications

Vane Hydraulic Pump

A vane hydraulic pump uses sliding vanes inside a rotating chamber. It offers smoother flow than gear pumps and is often used where quieter operation is needed.

Key features:

- Smooth and quiet

- Moderate efficiency

- Good for medium-pressure systems

Piston Hydraulic Pump

Piston pumps are the heavy hitters. They use pistons moving back and forth to create flow and can handle very high pressures.

Key features:

- High efficiency

- Excellent pressure control

- Used in demanding industrial applications

Each hydraulic pump type serves a purpose, and choosing the right one makes all the difference.

Key Components of a Hydraulic Pump Explained

A hydraulic pump may look complex, but it’s made up of a few essential parts working together. Knowing these parts helps build trust and understanding.

Common components include:

- Housing: The outer body that holds everything together.

- Inlet port: Where hydraulic fluid enters the pump.

- Outlet port: Where fluid exits under pressure.

- Rotating elements: Gears, vanes, or pistons that move the fluid.

- Shaft: Connects the pump to a motor or engine.

- Seals and bearings: Prevent leaks and reduce friction.

Each component plays a role, and when they work in harmony, the hydraulic pump delivers reliable performance day after day.

Applications of Hydraulic Pump Across Industries

The hydraulic pump is everywhere, even if you don’t notice it. Its ability to deliver controlled power makes it a favorite across many industries.

Common Uses of Hydraulic Pump

- Construction equipment like excavators and cranes

- Manufacturing machines and presses

- Agricultural machinery such as tractors and harvesters

- Automotive systems like power steering and brakes

- Aircraft control systems

- Marine equipment and ship steering systems

From lifting heavy loads to making precise movements, the hydraulic pump proves its value time and again.

Advantages of Using a Hydraulic Pump System

Why do so many industries trust the hydraulic pump? Because it offers a powerful mix of benefits that’s hard to beat.

Major Benefits

- High power output: Handles heavy loads with ease

- Smooth operation: Provides steady and controlled motion

- Durability: Built to last under tough conditions

- Efficiency: Transmits power with minimal energy loss

- Flexibility: Works in a wide range of environments

Put simply, a hydraulic pump delivers strength without drama. It just works and keeps working.

Hydraulic Pump vs Other Pump Types

To truly appreciate the hydraulic pump, it helps to compare it with other pump systems.

| Feature | Hydraulic Pump | Electric Pump | Pneumatic Pump |

|---|---|---|---|

| Power Output | Very high | Medium | Low to medium |

| Control | Excellent precision | Good | Less precise |

| Fluid Used | Hydraulic oil | Water or fluids | Air |

| Load Handling | Heavy loads | Light to medium | Light loads |

| Durability | Extremely high | Moderate | Moderate |

This table shows why the hydraulic pump remains the top choice for heavy-duty and precision applications.Maintenance Tips to Extend Hydraulic Pump Life

A hydraulic pump is reliable, but it still needs care. Regular maintenance keeps it running efficiently and prevents costly breakdowns.

Best Practices for Hydraulic Pump Care

- Check hydraulic fluid levels regularly

- Use clean, high-quality hydraulic oil

- Replace filters on time

- Monitor for unusual noise or vibration

- Inspect seals and connections for leaks

A little attention goes a long way. Proper care ensures your hydraulic pump stays strong and dependable for years.

Common Problems in Hydraulic Pump and How to Avoid Them

Even the best hydraulic pump can face issues if ignored. The good news? Most problems are preventable.

Typical Issues

- Cavitation due to low fluid levels

- Overheating from poor cooling

- Loss of pressure caused by worn parts

- Noise from air in the system

Avoiding these problems is often as simple as regular inspections and correct operation. When in doubt, early action saves time and money.

Safety Considerations When Working With Hydraulic Pump Systems

Safety always comes first. A hydraulic pump operates under high pressure, and careless handling can be risky.

Important Safety Tips

- Never check for leaks with bare hands

- Release system pressure before maintenance

- Wear proper protective equipment

- Follow manufacturer guidelines strictly

Respecting the power of a hydraulic pump keeps both people and machines safe.

Innovations and the Future of Hydraulic Pump Technology

The hydraulic pump isn’t stuck in the past. Modern technology is making it smarter, cleaner, and more efficient.

Emerging Trends

- Energy-efficient pump designs

- Smart sensors for real-time monitoring

- Reduced noise and vibration systems

- Environmentally friendly hydraulic fluids

These innovations show that the hydraulic pump is evolving, staying relevant in a world that demands efficiency and sustainability.

Choosing the Right Hydraulic Pump for Your Needs

Selecting the right hydraulic pump depends on several factors. There’s no one-size-fits-all answer, but careful planning helps.

Key Factors to Consider

- Required pressure and flow rate

- Type of application

- Operating environment

- Budget and maintenance needs

Making the right choice upfront ensures smooth operation and long-term satisfaction.

Final Thoughts on the Importance of Hydraulic Pump Systems

In the end, the hydraulic pump stands as a symbol of reliable power and smart engineering. It transforms simple fluid movement into controlled force, making modern machinery possible. From massive industrial systems to everyday equipment, the hydraulic pump proves its worth again and again.

As technology advances, the hydraulic pump continues to evolve, offering better efficiency, safety, and performance. With proper selection, care, and understanding, a hydraulic pump isn’t just a component it’s a long-term investment in strength and reliability.

Whether you’re learning, designing, or maintaining a system, trusting the hydraulic pump means trusting a proven solution that gets the job done, no matter the challenge.

You may also read

EOIR Automated Case Information: A Complete and Trustworthy Guide for Immigrants and Families